Case Studies

- Below Strain gauges is bonded on Huge POWER TRANSFORMER of one of the Worlds Branded Company to detect VIBRATIONS through this Analysis. For that ROSSETTE type Strain gauge is Used to detect Vibrations from multi Axis.

We have found Vibrations below 11 micro strain while online Inspection in front of Buyer & JOB is Certified Excellently based on this Strain Gauge Analysis.

- Following photos of Stress Analysis done on newly developed Rotary CRANE, with 30 ton Capacity, Manufactured by very Big Company in INDIA (Worldwide known Name).

We have done this Stress Analysis by Bond strain gages in 14 different locations, that was defined by FEA (Finite Element Analysis) Computer Software.

Strain of all Gauges was measured at a time through Multi Channel Strain Data Logger. While testing of this Crane with Full Load & 360 degree Rotations our Client is Satisfied with our JOB, because there was a Challenge to Measure all data with Rotational Boom of the Crane.

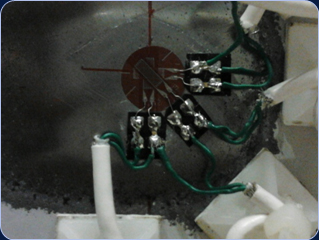

- We have done stress Analysis on Aluminium Rod, as below along with 44 Pasted Gauges (11 Full Bridge Configurations)

Length of the Rod just 45 cm & Diameter was 3 cm only. Main criteria was Bonding the Gauge on Round Surface area & Small Periphery of Rod. We have got Successful Strain output by bonding the gauge on Specified Place.